We are currently testing a brand spanking new Kornit printer for breathable polyester clothing. Find out what this means for you and your Shop.

Breathable sportswear is usually made of 100% polyester. The material has definite advantages for athletes: it doesn’t absorb any liquids and its woven structure ensures that sweat can evaporate quickly and easily. Polyester T-shirts are therefore becoming increasingly popular with sporty customers.

Why polyester printing?

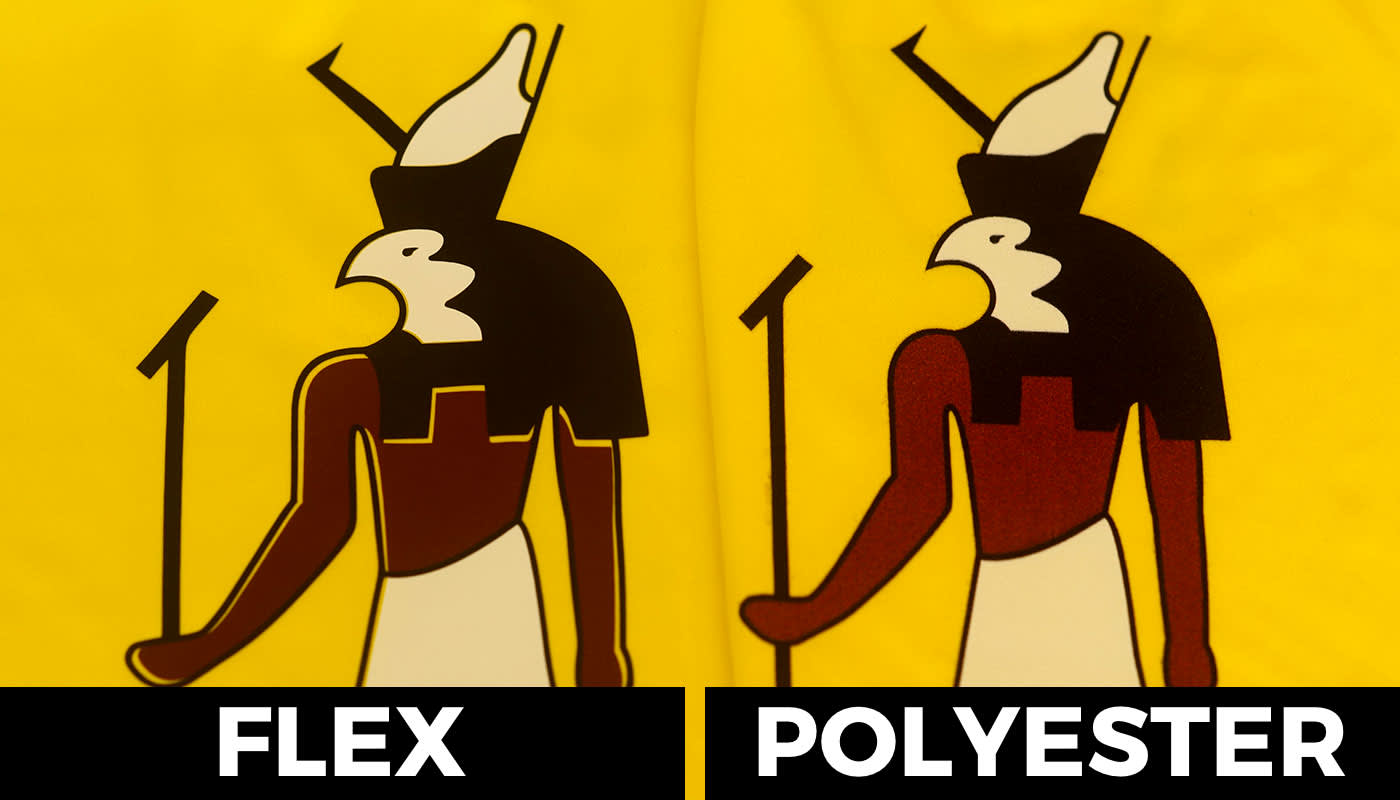

So polyester has some pretty cool features, but the material has presented us with a number of challenges: Up to now, we have only offered the plot printing process for polyester clothing – i.e. printing with flex or flock foils. This printing process had a number of disadvantages:

- The product is no longer breathable in the areas printed with the foil.

- Foil printing allows a maximum of only three colors and is unsuitable for detailed graphics

- The likelihood of production flaws is high. This is because the foils shrink slightly under the heat of the printer, causing issues with the flexibility and comfort of the finished print

What are the advantages of polyester printing?

Digital printing with ink has the following advantages:

- Our new Kornit polyester printer can print any number of colors. The print is flexible and does not tear.

- Breathability is maintained, regardless of the size, colors detail of the design

- Printing is faster, so the goods can be delivered faster

We have very strict quality standards for our printing, our products and, of course, durability – especially for garments that are subject to heavy wear during sports. The prints need to withstand all the dirt and sweat on the field as well as frequent washing. That’s why we test the new printing process extensively before offering it as an additional printing method.

Our challenge: durability

Normally, a printed design is fixed onto the material by heating the ink as it dries to approx. 165° Celsius (that’s about 330° F). The machine we use for this is basically like an enormous hair dryer. But this process doesn’t work with polyester. If it’s heated too much, the dye from the polyester material melts and mixes with our printing ink. So printing a red polyester shirt with white ink would result in a pink design. Drying is therefore only possible at lower temperatures. But then we have the problem that the ink isn’t fixed strongly enough, detaches too fast and looks faded after two washes.

This is why we are experimenting with different products, brands and ink—and we’ve just made our first breakthrough! We’ve finally developed a process at approx. 135° Celsius that reliably meets all our requirements.

When do we start?

We’re confident that we will soon be able to start mass production. That means we will roll out the new printing technology for more and more business areas, continue to gather feedback and optimize it. We hope that we will be able to offer polyester printing for your Shop by Christmas 2020. So start looking forward to it and thinking about how you can develop new target groups for your Shop thanks to this new printing technology.

Which target groups could these be for your Shop? Which products do you want to see offered in polyester? Let us know in the comments.